About IBA RadioPharma Solutions

Choose excellence for your radiopharma production

IBA is the world leader for the supply of PET & SPECT cyclotrons for radiopharmaceuticals production. Headquartered in Belgium, IBA installed and supports over 350 cyclotrons across the world.

Based on 35 years of experience, IBA RadioPharma Solutions helps your nuclear medicine department to design, build and operate PET centers to produce radiopharmaceuticals used for the detection and treatment of cancer and other critical diseases.

Why PET?

Cardiac PET (positron emission tomography) imaging is a fast-growing clinical tool endorsed by well recognized clinical guidelines and has demonstrated its high accuracy and precision. This powerful non-invasive imaging technique can assess myocardial blood flow (MBF) throughout the coronary circulation system, epicardial vessels and microvasculature, making it more effective and more efficient as a functional imaging modality.

Cardiac PET imaging offers an array of advantages that make it more attractive than SPECT imaging for assessing coronary artery disease.

- Wealth of clinical information

The reproducible and fast quantification of myocardial blood flow (MBF) from myocardial perfusion PET generates greater insight into cardiovascular physiology and pathology. - Higher resolution and advanced image acquisition/reconstruction

PET provides better quality static and ECG gated images and dynamic quantitative data on myocardial blood flow during peak stress and at rest; a unique feature of PET. - Better sensitivity and specificity

The combination of data from static, ECG-gated and dynamic images makes PET a more sensitive and specific functional imaging modality for the detection of coronary artery disease, reducing downstream costs. - Lower radiation exposure

PET imaging uses radiotracers with shorter half-lives for myocardial perfusion imaging, reducing patient and staff radiation exposure.

Why 13N-Ammonia?

The fast track to accurate diagnosis

13N-Ammonia is an effective diagnostic tool that improves patient management by accurately detecting coronary artery disease (CAD) due to its short positron range, high first-pass extraction and retention properties in the myocardium. Increasingly recognized by leading cardiac imaging institutes, 13N-Ammonia is experiencing a promising adoption for cardiac PET imaging, as it provides diagnostic studies of consistently high-quality, regardless of patient size or gender.

- FDA-approved

- Scalable solution for larger screening volumes

- Range of stress protocols including exercise testing

- Improved prognostic and diagnostic accuracy

- Lower radiation exposure

- Quantitative assessment of myocardial blood flow (MBF)

Why Akuracy®?

13N-Ammonia total solution for cardiac PET imaging

- Full independence

AKURACY® enables cardiac imaging centers to achieve full independence from external radiotracer suppliers by providing on-demand, in-house production capabilities. - Nuclear Activation free

AKURACY® provides an activation-free solution, significantly reducing nuclear activation and minimizing radioactive waste management challenges, resulting in a safer, more efficient, and cost-effective production process. - Ease of use

The entire process is controlled by high-level software with an intuitive interface that can be operated by qualified personnel. From tracer production to dose availability, on demand and tailored to your schedule. - Low OpEx

Fully automated production results in higher daily patient throughput, reducing your operating expenses and saving your time.

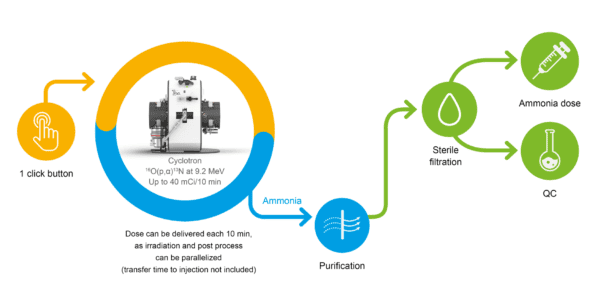

Akuracy®, 13N-Ammonia on-demand production

The IBA Akuracy® solution is an innovative user-friendly system designed for the automated production of 13N-Ammonia. The system is a push-button solution that any qualified technologist can easily operate out of the cyclotron area directly from the PET/CT scanner control room itself, making it a convenient and efficient tool for producing 13N-Ammonia on demand.

Akuracy® is designed to produce a ready-to-use 13N-Ammonia dose about every 10 minutes, significantly improving workflow efficiency with enhanced scheduling flexibility. The system includes in-line advanced quality control features, ensuring the production complies with the pharmacopeial quality standards.